The possibilities of 3D printing in the aftermarket car electronics installation trade are virtually limitless, and now by offering fabrication training that includes 3D printing, industry innovator Mobile Solutions is helping car audio specialists to deliver the cutting edge at their Tempe, AZ facility. The company’s first training class integrating 3D printing took place in May.

Mobile Solutions has adopted 3D printing into their fabrication training to allow car electronics installation experts to expand their range of abilities. Aside from the rapid prototyping of new tooling, production of automotive shapes and complex, vehicle-specific applications means the field is open to innovation.

Mobile Solutions USA delivers training for custom automotive electronics, audio and interior installations, and their patented Smart Templates brand of design tools serve the aftermarket automotive technician, fabricator, and retail store community.

The president of Mobile Solutions, Bryan Schmitt, started his business in 2005, and the company has two divisions; an installation fabrication school recognized as one of the finest in the 12 volt industry, and a second which sells unique installation and fabrication tools and supplies.

Schmitt has also served as a professional technical speaker and trainer, and he’s trained thousands of technicians around the world with a series of innovative seminars.

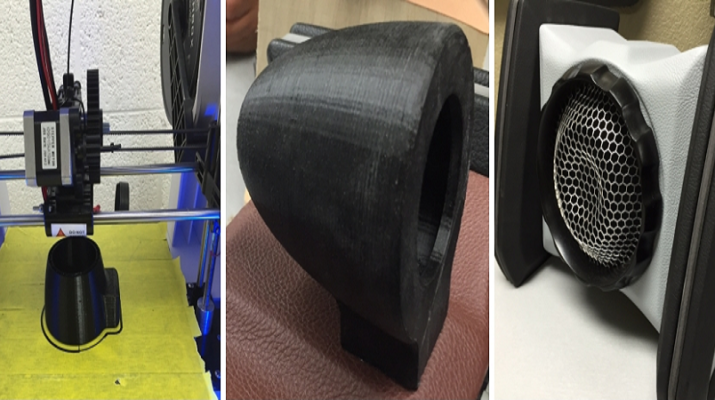

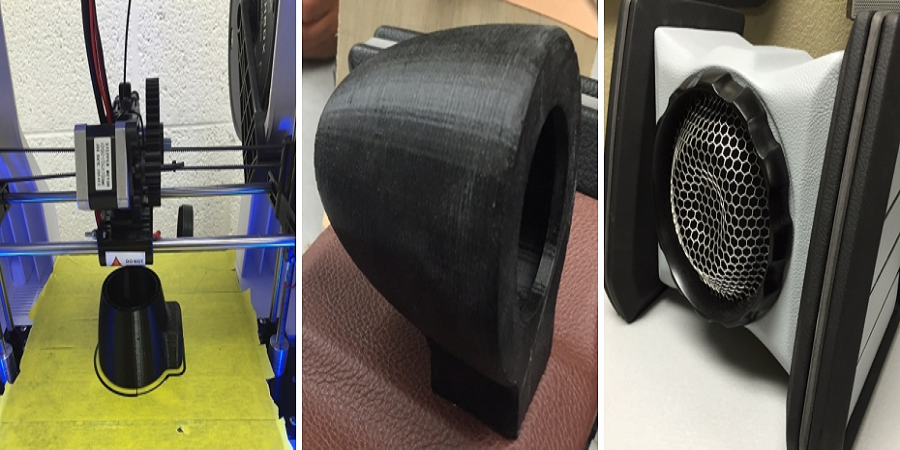

“This was the first class where we’ve actually used 3D printing automation for fabrication techniques,” Schmitt says. “3D printing allows technicians to build things that could never be achieved with one-off, hand done prototyping that’s typical in the fabrication world.”

Working alongside Mark Klettee from Car Audio Fabrication and Rommel Medina, Schmitt says the Mobile Solutions 3D Fabrication Class created the world’s first 3D printed press grill mold.

He says the printer ran following the classes, and the following morning, the 3D printed parts were ready to use.

According to Schmitt, more than 20 custom grills were molded with the tooling – without any wear and tear issues. He says that result is a demonstration of the new and more profitable ways specialist retailers can leverage their labor hours for maximum profit and creativity.

Schmitt says the next Mobile Solutions 3D training class is scheduled for this fall. You can find a schedule and more information about the company here. Do you think you could design and build a custom piece for the interior of your car? Let us know in the 3D Printer Fabrication Training forum thread on 3DPB.com.

When it comes to 3D real estate visualization in the USA, our service provides the perfect solution for bringing property listings to life. Through our platform, you can easily access cutting-edge 3D renderings that showcase your real estate projects in a way that attracts potential buyers and investors. Whether it's residential, commercial, or mixed-use properties, our team of experts uses advanced technology to create immersive visualizations that highlight the best features of your property, making it easier for clients to imagine the space as their own.

Through our website, you can quickly get high-quality 3D real estate visualizations that are tailored to your specific needs. With our help, you'll stand out in the competitive real estate market by offering potential buyers a realistic, interactive view of your property. Our efficient process ensures a fast turnaround time, while our attention to detail guarantees that every aspect of the property is represented accurately, giving you a powerful marketing tool to promote your real estate listings.