With companies currently rushing to industrialize 3D printing consultants are in high demand. Many industrial, medical and aviation firms are looking for a steady hand to guide them in 3D printing land. Our set of technologies is complex to implement at scale and this means that real expertise and experience is needed to manufacture using 3D printing. Betatype was founded in 2012 to enable companies to make functional 3D printed parts. The company works at the intersection of design, material science and engineering to make parts that perform. Their Engine technology is a software platform that the team can use to reduce part costs and optimize topologies and designs. We’ve published a number of interesting Betatype case studies at 3DPrint.com such as this one about a 3D printed watch strap, automotive production, Formula One and parts consolidation. We are impressed with the team’s methodologies and projects but most of all on their realism. Due to this, we thought it a good idea to interview Sarat Babu, Betatype’s CEO.

What kind of projects have you done with customers?

“The first is for those who have complex functional requirements and they’re looking to explore what AM can do. In this phase we are either designing for them or collaborating with their design teams to develop components and parts that not only answer their functional requirements but also their productivity targets. We’ve developed a unique set of technologies for process optimisation in laser powder bed fusion and this provides us with a keen insight into how to design parts that are also economically viable.

The second is for customers who have already designed parts and are looking for ways to get more productivity or precision out of laser powder bed fusion systems. Here we directly apply our optimisation techniques on the customer’s parts to get them to where they want to be in terms of manufacturing.”

What advice could you give me if I was a large manufacturing company and I’d want to get started with 3D Printing?

“Working on the assumption that you are talking about additive for production applications, which is where we specialise (for prototyping and tooling I would make recommendations elsewhere) Additive Manufacturing technologies are still relatively immature platforms to develop solutions on, and while there is no doubt in my mind that today’s technology is completely capable of delivering compelling capability, its important to understand the R&D work that needs to be done to implement the technology in serial production. Because of this determining applications spaces that you want to address is an important first step in understanding if AM is the right technology to take on.”

What about if I’m a SMB?

“Frankly, I think its very difficult for SMB’s to grab onto these technologies for serial production — both in terms of a steep learning curve and a high price — but the landscape is changing and OEM’s and manufacturers are providing ways for smaller players to access their technologies through collaboration and partnerships, which is where we can provide support. The key is to get your hands on the technology and understand if your bandwidth and the system’s capability match your application, is cost-effective (or at least competitive) and adds value across the lifetime of the product or part.”

What application areas do you see opening up?

“What makes this a particularly exciting time from a design perspective is that the answer is unclear — we’ve worked on projects with companies in sectors where AM is very much a part of their emerging landscape but also with companies where you would typically think AM makes little sense where both projects have been excellent candidates for today’s technologies. Of course advancing technologies will inevitably increase the opportunity in established sectors (aerospace / medical etc.) and open up new application areas here as well as. In terms of new applications in unidentified areas – we don’t know what we don’t know yet. But the Uniform Wares’s watch strap is a great example of how and where new opportunities can open up.”

What are the next products that will be industrialized with 3D Printing?

“I think this is one of the biggest questions the industry faces right now, and frankly I don’t have an answer for it.”

What are some of the 3D printing technologies that you’re most interested in?

“I’ve always believed the power of 3D printing technologies is in their ability to really control process to a level that is unheard of versus any prior manufacturing process. It’s here I think that something of the most exciting application innovations are going to occur, building parts that simply aren’t possible any other way, where even though they may not be the technologies that bring 3D printing to the mass market they carve out a real home for serial AM production.”

What are some key developments in 3D Printing materials?

“The most exciting material developments for me are when AM is used to deliver performances out of materials that are beyond the scope of the traditional process. Creating all new materials as Lawerence Livermore National Laboratory demonstrated last year by creating mechanical properties in Stainless Steel beyond what can be achieved with traditional processes.”

What are the key stumbling blocks in 3D Printing implementations?

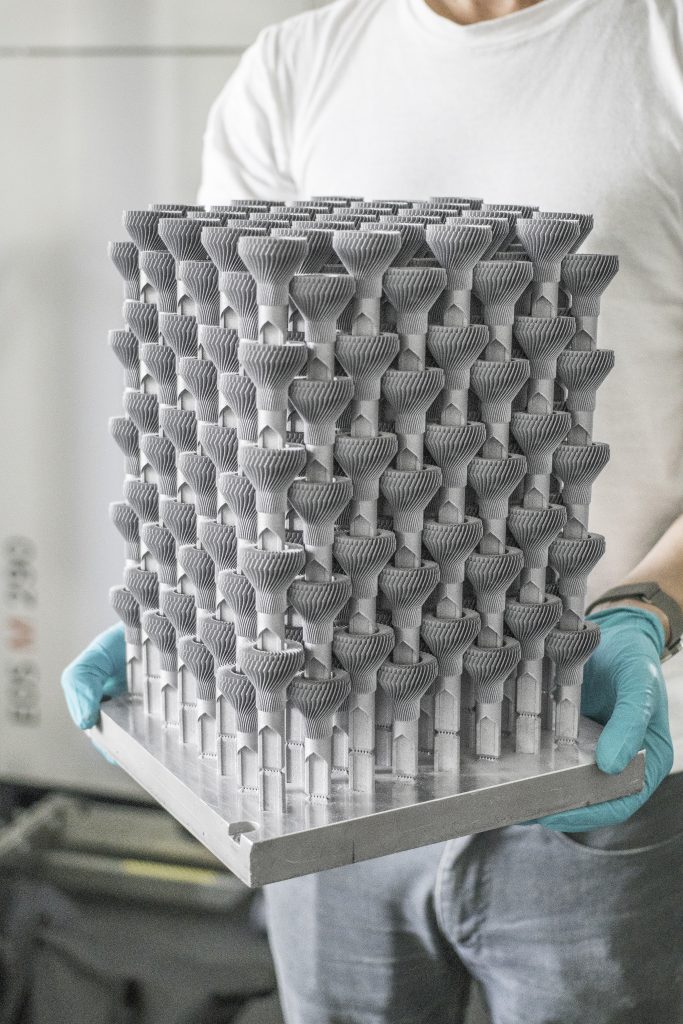

“Often I think the focus in the industry is heavily biased towards the technology rather than on the challenges of nurturing the creativity that will be required to actually make use of the technology. What we need now more than ever is people engaging with these technologies and exploring the full spectrum of applications that can possibly be delivered. Application development (and research), whether directly or through collaboration, is key to driving the implementation of additive technologies. Other stumbling blocks that are often cited are productivity in terms of build speeds and volumes of parts. These are exactly the barriers we are overcoming with the unique technologies that Betatype has developed. They are real solutions to these problems when applied in the right way.”

What is Betatype?

“Betatype is an AM solutions company; we make AM perform. We have developed technology solutions for AM which combined with our design and engineering expertise make it perform better – to achieve greater part functionality, manufacturing productivity by reducing cost per part at higher volumes for highly complex parts. We believe that this, in combination with our understanding and expertise with the PBF process is what sets us apart as a compelling partner.”

What do you hope to achieve?

“Our aim is ultimately to help companies explore what is possible in AM and with the aid of our technology get them to serial production.”

When it comes to 3D real estate visualization in the USA, our service provides the perfect solution for bringing property listings to life. Through our platform, you can easily access cutting-edge 3D renderings that showcase your real estate projects in a way that attracts potential buyers and investors. Whether it's residential, commercial, or mixed-use properties, our team of experts uses advanced technology to create immersive visualizations that highlight the best features of your property, making it easier for clients to imagine the space as their own.

Through our website, you can quickly get high-quality 3D real estate visualizations that are tailored to your specific needs. With our help, you'll stand out in the competitive real estate market by offering potential buyers a realistic, interactive view of your property. Our efficient process ensures a fast turnaround time, while our attention to detail guarantees that every aspect of the property is represented accurately, giving you a powerful marketing tool to promote your real estate listings.