ExOne is a pioneer in sand 3D printing, licensed since 1996 to continue developing industrial inkjet 3D printing originally created by engineers at Massachusetts Institute of Technology (MIT) for use with a variety of materials, to include sand and ceramic. Over decades, the North Huntingdon, Pennsylvania-headquartered company has evolved into one of the undisputed leaders in binder jet 3D printing technology.

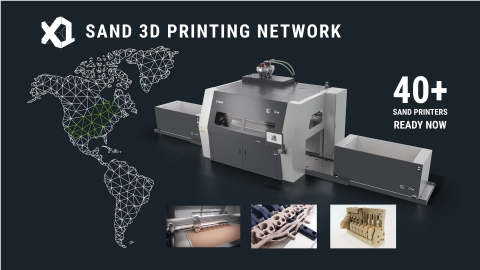

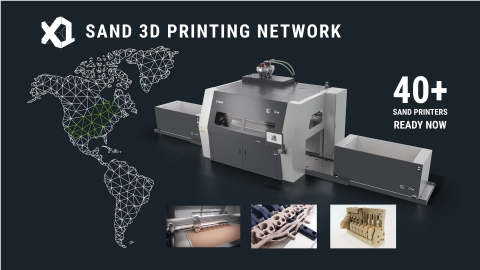

With the inception of its 3D Sand Printing Network, ExOne is solidifying its position further, along with providing greater accessibility for its customers in North America. With 40 binder jet 3D printers owned mainly by pattern shops and foundries within the US, Canada, and Mexico, S-Max and S-Print systems are available for efficient production of molds and cores (usually finished within three to five days).

Sand 3D printing—and especially on the large scale—serves as a powerful and versatile industrial tool for critical applications like automotive, aerospace, and agriculture. Particles of sand are bound together by glue, resulting in a fabricated structure—whether it is a prototype, functional part, or a mold meant for creating other items. Cores can be created in one piece, saving time, money, and eliminating the need for assembly later, as well as clean-up.

This type of technology may not be as visible in the additive manufacturing mainstream, but behind the scenes, for many companies, it is the key to the production of metal casted molds and cores which are then used to make other parts. Industrial users have the ability to create new designs not otherwise possible, along with producing quality, high-performing molds that can also be created on-demand—eliminating the necessity for storage.

“The new ExOne Sand 3D Printing network can help manufacturers easily locate an ExOne sand 3D printer that best meets their needs,” said John Hartner, ExOne CEO. “What’s more, our network can help ensure a steady supply of sand molds and cores for metal castings, especially during a crisis, as well as enable reshoring of key parts that may be difficult to ship during the ongoing COVID-19 pandemic.”

Sand 3D printers continue to expand services for companies still mainly engaged in conventional methods like CNC machining, and the technology continues to be the source of research focused on investigating the benefits, as well as improving metal molds.

[Source / Images: Business Wire]

When it comes to 3D real estate visualization in the USA, our service provides the perfect solution for bringing property listings to life. Through our platform, you can easily access cutting-edge 3D renderings that showcase your real estate projects in a way that attracts potential buyers and investors. Whether it's residential, commercial, or mixed-use properties, our team of experts uses advanced technology to create immersive visualizations that highlight the best features of your property, making it easier for clients to imagine the space as their own.

Through our website, you can quickly get high-quality 3D real estate visualizations that are tailored to your specific needs. With our help, you'll stand out in the competitive real estate market by offering potential buyers a realistic, interactive view of your property. Our efficient process ensures a fast turnaround time, while our attention to detail guarantees that every aspect of the property is represented accurately, giving you a powerful marketing tool to promote your real estate listings.