In ‘A Feasibility Study for the Production of Three-dimensional-printed Spine Models Using Simultaneously Extruded Thermoplastic Polymers,’ a group of Mayo Clinic researchers – William Clifton , Eric Nottmeier, Aaron Damon, Conrad Dove, Selby G. Chen, and Mark Pichelmann – explain how and why they 3D printed models of the spine for surgical simulation.

Medical simulation can be invaluable for residents in training, although before the advent of availability with 3D printing, there was not quite as much accessibility—or possibility; in fact, cadavers are still considered the ‘gold standard’ for training with simulators, but they are more expensive, high-maintenance, and highly regulated.

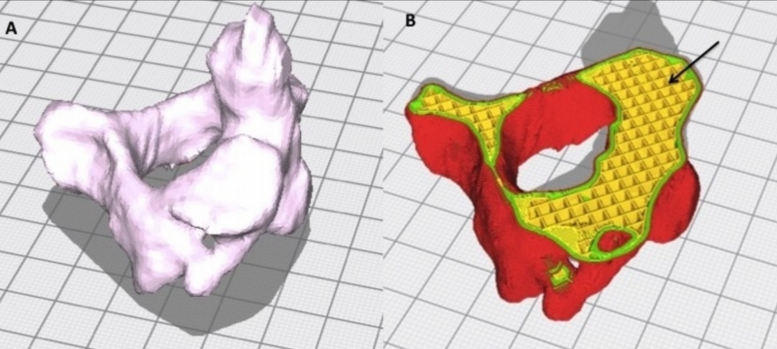

Looking at the trend toward creating simulators that can mimic the feeling of penetrating cortical bone into cancellous bone during spinal instrumentation, the authors created three lumbar vertebrae and 20 C2 vertebrae models, using an Ultimaker S5 3D printer with PLA filament, and PVA (polyvinyl alcohol)—used to imitate cancellous bone inside the shell. While PVA is a plastic that tends to be spongy and water-soluble, it is generally not used in creating stand-alone structures, and has had limited use. With the accompaniment of PLA, however, parts are less brittle and exhibit greater ductility. The researchers state that here, the two materials are suitable for creating simulated bone.

The researchers reported good success with all the models. There were no failures reported in either hardware or materials, and the PLA/PVA models proved to be superior over the single material models, and in tactile feedback, the researchers said that they ‘accurately represented the sensation of in vivo instrumentation during pedicle probing, pedicle tapping, and screw placement.’

Previously, popular 3D printed materials for fabricating vertebral bony anatomy for biomechanical testing and instrumentation have been used with a wide range of different results:

- A variety of resins

- Acryl butadiene styrene (ABS)

- Nylon

- Polylactic acid (PLA)

- Thermoplastic urethane (TPU)

“Another limitation of most previously published models is their constraint of a one material print. Literature suggests that decreasing the print infill percentage adequately simulates the density change of cortical bone to cancellous bone. These findings have been quantified with regards to subjective user feedback and biomechanical stress with good results,” stated the researchers. “A possible limitation of this modeling technique is the ultrastructure of the print does not completely simulate the complex characteristics of human vertebrae.

“Bone strength is composed of two properties: bone mass, or quantity of material, as well as the bone quality, or mechanical properties of the material. Previous spinal models have incorporated these parameters individually, but not collectively.”

Shells printed with dual materials were selected because of anatomical differences and instrumentation placement methods and were limited to only the lumbar and cervical forms. Ultimately, the PLA/PVA method was promising for use in both educational and biomechanical simulators.

“This has large implications for the spinal instrumentation industry as well as resident training. This concept and design of simultaneous multi-material printing using our unique infill algorithm have not been yet reported in the medical literature,” concluded the researchers. “Further educational and biomechanical testing on our design is currently underway to establish this printing method as a new standard for spinal biomimetic modeling.”

Medical models overall have become extremely helpful in medicine, and while simulators may sometimes be larger and more complex in design, smaller models are often used for diagnosing conditions like tumors, training and surgical planning with 3D printed models of the brain, and even those that allow parents to plan for babies with medical issues. Find out more about how 3D printing is making a positive impact with progressive simulators here. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: A Feasibility Study for the Production of Three-dimensional-printed Spine Models Using Simultaneously Extruded Thermoplastic Polymers]

When it comes to 3D real estate visualization in the USA, our service provides the perfect solution for bringing property listings to life. Through our platform, you can easily access cutting-edge 3D renderings that showcase your real estate projects in a way that attracts potential buyers and investors. Whether it's residential, commercial, or mixed-use properties, our team of experts uses advanced technology to create immersive visualizations that highlight the best features of your property, making it easier for clients to imagine the space as their own.

Through our website, you can quickly get high-quality 3D real estate visualizations that are tailored to your specific needs. With our help, you'll stand out in the competitive real estate market by offering potential buyers a realistic, interactive view of your property. Our efficient process ensures a fast turnaround time, while our attention to detail guarantees that every aspect of the property is represented accurately, giving you a powerful marketing tool to promote your real estate listings.