When discussing the future of the 3D printing industry with various experts within the field, about half of them believe we will one day have 3D printers in virtually every home, while the other half believes that the majority of 3D printing will be provided by services such as Shapeways and Sculpteo, or through web-like hubs such as 3D Hubs. The reasoning for the latter train of thought is that there will always be incredibly expensive high-performance machines out there making it more economically feasible for users to outsource the printing, rather than purchase various machines costing as much as six figures apiece.

Shapeways, headquartered in New York City, obviously sees things in a more service-oriented light as well. They are the leaders when it comes to 3D printing as a service. One of the reasons for their lead within this market is the fact that they have an expansive number of materials with which they can fabricate objects on a wide range of 3D printers. Today, the company has announced that yet another material, porcelain, will be made available, and slowly rolled out to all Shapeways users by early next year.

The porcelain material is truly groundbreaking when it comes to 3D printing, enabling quite an array of additional applications and products which would not have been 3D printable in the past. The material, which was developed in part by Dr. Stuart Uram of Core Cast Ceramics, is able to be used with Shapeways’ Selective Laser Sintering (SLS) machines. These are the same machines which produce items fabricated with the company’s popular Strong and Flexible material.

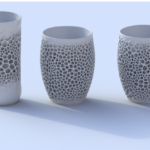

“The process for this material is closer to traditional ceramics than other methods of 3D printed ceramics production, so the end results have the beautiful quality of traditional ceramics with the unique design intricacy you can only get through 3D printing,” stated the company.

The porcelain is not actually being printed; instead, SLS machines will print molds which are then used to cast the items desired, meaning extremely fine details will be made possible.

There are several key benefits to printing with this amazing new porcelain material. Because of the strength of the material, larger items may be fabricated without the worry of breakage, while several classic porcelain colors, such as matte black and cobalt blue, will be available, enabling designers to create objects which appear to have been manufactured by traditional methods. Additionally, porcelain is dishwasher and oven safe, meaning no more worries about whether or not your 3D print will hold up under stress.

Initially, this new material will be rolled out to select designers with intentions to make it available to all Shapeways designers early in 2015. Let us know if you have tested this new material out. Leave your feedback in the Shapeways Porcelain Material forum thread on 3DPB.com.

When it comes to 3D real estate visualization in the USA, our service provides the perfect solution for bringing property listings to life. Through our platform, you can easily access cutting-edge 3D renderings that showcase your real estate projects in a way that attracts potential buyers and investors. Whether it's residential, commercial, or mixed-use properties, our team of experts uses advanced technology to create immersive visualizations that highlight the best features of your property, making it easier for clients to imagine the space as their own.

Through our website, you can quickly get high-quality 3D real estate visualizations that are tailored to your specific needs. With our help, you'll stand out in the competitive real estate market by offering potential buyers a realistic, interactive view of your property. Our efficient process ensures a fast turnaround time, while our attention to detail guarantees that every aspect of the property is represented accurately, giving you a powerful marketing tool to promote your real estate listings.